12. October 2020

ACAM connects decision-makers and peers of Additive Manufacturing and builds project consortia at its Annual Meeting Digital. Every year in fall the RWTH Campus Aachen is the gathering location for the decision-makers of the industry and the peers of research from throughout the world, where they exchange views, information, and experiences regarding Additive Manufacturing, as well as to determine the project consortia for the upcoming year. Due to the COVID-19 pandemic and the associated contact restrictions, ACAM set up this year a digital event platform, where its guests were also able to connect, learn, and network.

Additive Manufacturing continues to expand with new players entering the market and new technologies being developed. One of the ways that ACAM assists these companies is to nurture a trusting network that leverages research and industry collaboration. For this reason, ACAM offers every year two Community Meetings, which enable its industry members and research partners to discuss the future of additive manufacturing and build project consortia. One of them is the Annual Meeting, which took place on September 30, 2020.

This year ACAM reduces the boundaries between the digital and personal interaction

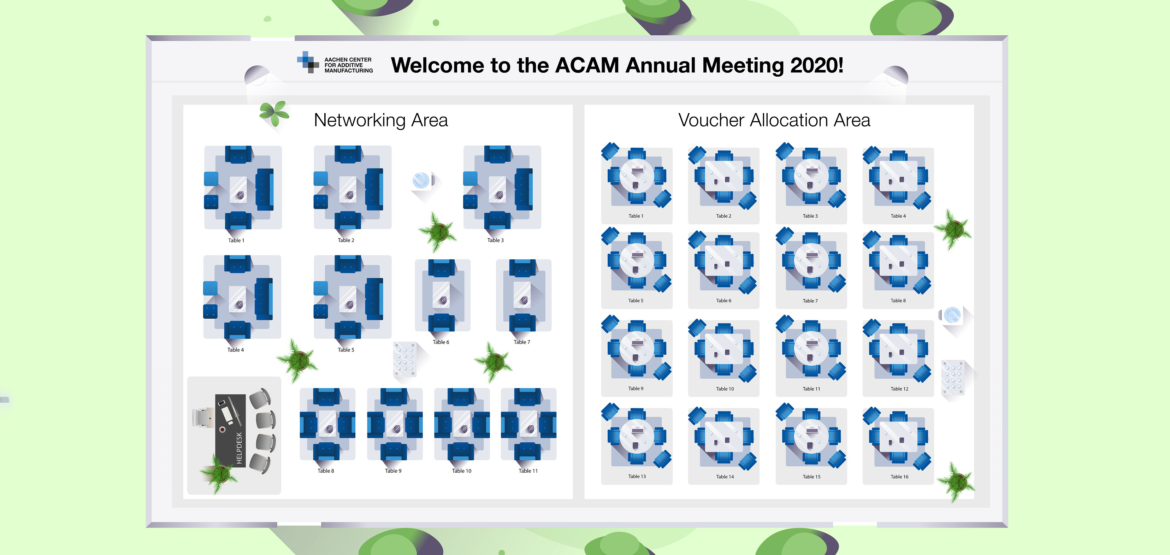

By knowing that sense of community is also crucial for business relationships, ACAM used the online platform Remo, to enable engagement and networking opportunities at the Annual Meeting. Just like at the physical event, the research partners presented the project topics designed according to suggestions and ideas of the whole ACAM community, so the industry members can choose the ones they are interested to support in the upcoming year. At this year’s event 16 topics were presented and ultimately 7 project consortia were formed. The topics are:

- Benchmark of Business Model Development for AM – Time-To-Market, Individualization, Agile Production

- Practical comparison of Binder Jetting Technologies

- Development of functionally adapted high-performance heat exchangers using Laser Powder Bed Fusion

- Development of an ultra-hard (> 800 HV) Fe-based alloy for Additive Manufacturing

- Functionalized coating and repair of tools using LMD/EHLA with direct finishing

- Processing high carbon steels by LPBF with advanced process strategies

- Technology benchmark for AM of copper materials

The ACAM community continues to grow

This year’s annual meeting was also used as an opportunity to introduce Nissan as a new basic member of the community.

ACAM is still open for new members. Depending on the scope of the desired cooperation, the interested companies can choose between three different membership models with different range of services: the basic, business, or cooperation membership. These models provide an individual, comprehensive access to the network’s service and are open to national and international companies.

A holistic perspective on Additive Manufacturing in Aachen

The future development of Additive Manufacturing especially in the areas of digitalization, new technologies, and technology transfer will be of major importance for the ACAM and its partners in order to fully industrialize the technology. Before the background of the corona pandemic, strong networks become even more important for this common goal. Both trends, strong networks, and deep technological expertise are two of the main drivers of ACAM’s activities, which require even more attention to our future way. In order to provide time and space for these tasks, Prof. Schleifenbaum will strengthen his engagement within the ACAM and has terminated his secondary employment at Fraunhofer-ILT at the same time. This decision will also foster ACAM capabilities to serve as the integrated key account for all AM activities on Aachen Campus, supported by more than 10 research partners from RWTH Aachen University, FH Aachen, Fraunhofer IPT, and ILT.

Contact

Ingrid Bongiovanni Roll

Marketing & Community Manager

T +49 241 9426 1025

Press release in PDF